Ty needed to get some really precise holes drilled in his frame assembly. My pillar drill is incredibly inaccurate, and those holes were sort of make it or break it for the project- As luck would have it, Olav had acquired a professional pillar drill /milling machine some time ago, and we drove to the workshop where it still is. (He hasn't moved it home yet).

We got all the holes drilled, two that were square to the surface, two that were at a 15.6 degrees and two that were 14.7 degrees to the surface (like all chair making angles it is measured from 90 degrees.)

This machine was up to the task and I am a quite a bit jealous at Olav for having such a nice machine.

Good thing that I can borrow it though :-)

Brian started adzing out his seat, and he has made good progress.

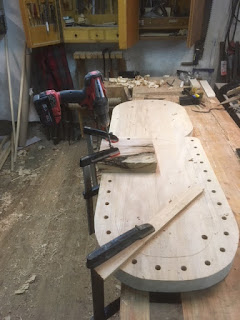

I worked on the seat and got all the holes laid out and drilled. Next I made the legs and that was done with the copy attachment on my lathe. This attachment works really well, and the whitebeam gave a nice surface. I am not a fast turner, but using this attachment made it both fast and I ended up having four identical looking legs.

Olav continued on the shaving horse, and was mostly occupied in making huge mortises in the base and the upper rest part.

Drilling on the Arboga drilling machine.

Ty in action.

14.7 degrees really is possible with this machine!

Drilling holes in the seat.

My drilling guide for ensuring 7 degrees holes.

Brian adzing away.

Turning a leg with the copy attachment.

Organized chaos. I am in awe, gentleman.

ReplyDelete-Mitchell

Hi Mitchell.

DeleteSorry for the late reply.

I am glad that you enjoy reading about the progress of the build. There was quite a bit of chaos in the end.

Especially when Brian decided to attack a wasp using a broom - while the wasp was resting on the window...

Brgds

Jonas

Everything's looking great, impressed with all the progress. Thanks for the frequent updates. I can't figure out what you're making yet, but don't want to do an online search -- waiting for you to reveal it.

ReplyDeleteHi Jeff.

DeleteSorry for the late reply.

There has indeed been a steady progress, though Ty was the only one to complete a chair within the official time frame of the event.

Brgds

Jonas

That realy was a great machine - have been contemplating how to get, and find room for one, myself..

ReplyDeleteIt was a great experience being part of DCBE. Learned a lot and had fun. A whole week doing only one thing is such a luxury that I need to do more often. Thank you for letting me be a part of the extravaganza!

Hi Ty.

DeleteYes that machine would be most welcome in my shop!

I am back on the job now, so I'd better get the blog up to date as well.

Completing the sack back nanny rocker revealed that Ray Schwanenberger was correct in saying that it is a fairly large and complicated build.

I am glad that you enjoyed participating in the event. It was nice to get to know you, and learn how to make custom router bits etc.

Best regards

Jonas