My original plan was to use some oak for the drawer fronts, and spruce for the sides,

In the meantime a golden opportunity presented itself.

One of the ships pilot ladders (a rope ladder) had broken one of the long steps, and was subsequently thrown out. These ladder steps are made out of some nice straight grained exotic wood, so I decided to see if I could reclaim them. Therefore I went dumpster diving in the common garbage dumpster that is on the ship, and below some heavy mooring lines and some old metal pails I got hold of the pilot ladder.

There were 4 narrow steps and one long step. The long step was the one that had been damaged.

So now the plan has changed from oak front / spruce sides to exotic front + sides and spruce bottoms.

I first re sawed the long step which was really easy. The smell of the wood is kind of like cheap plywood, and it is rather soft. It reminds me of the same type of wood that was used for making cigar boxes of (I have no idea what the species is). This long board will not be used for the tool chest, but for another project that will be revealed when we head back to sea.

The next task I carried out was to re saw some of the pallet sides to make material for the bottoms of the drawers. Re sawing something that is 7.5" wide is not a walk in the park when you have a cheap all round saw, but I managed to produce some thin boards that I can use after I have dressed them with a plane.

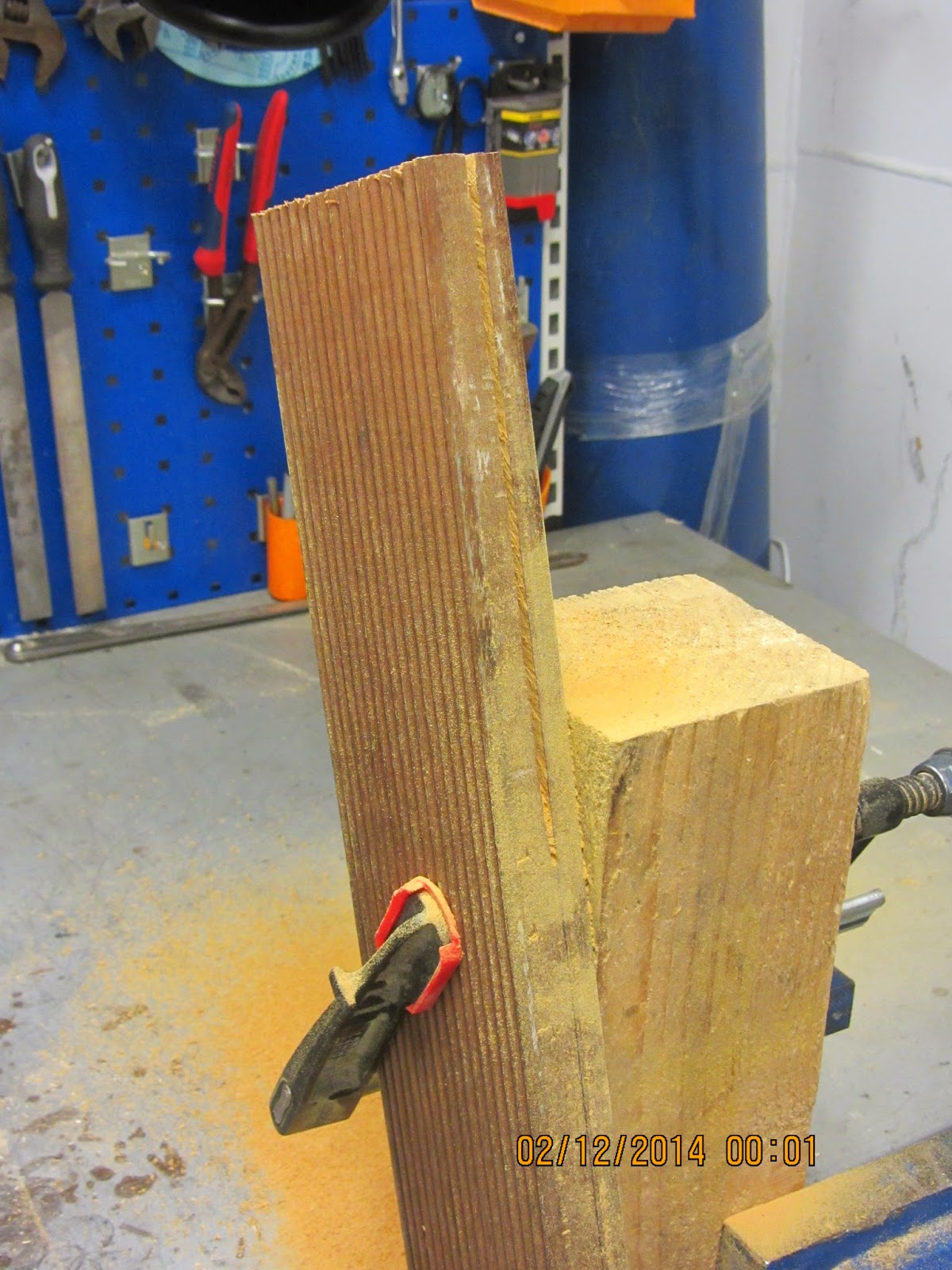

The short steps of the ladder were heavier than the long step, and they are definitely made out of some other species of wood. It doesn't smell like teak, but it seems like there is a lot of natural oil in the wood. Re sawing those boards were a lot harder than what I have tried before.

Each board measured 4.5" x 16" and it took me half an hour to re saw each one of them.

The good thing about all this hard work is that I get some exercise and I really appreciate my band saw and table saw at home.

The fall front of the chest was made last time I was on the ship, so I haven't done that one in between the re sawing.

It is made using tongue and groove construction for the rails and stiles, and the panel is inserted in a groove. I haven't attached the pins for sliding yet, nor have I made a mortise for the lock. I wan't to make the drawers first and then I can move back to the lid. Anyway, my idea for installing the lid requires it to be done pretty much when the chest has received some kind of finish, so I am not in a hurry.

Re sawing set up. This wood is hard!

The fruits of hard labour.

The front lid.

The front lid inserted in the chest.

The prize from dumpster diving.

I am amazed that you could resaw those boards that well with that saw. No way I could.

ReplyDeleteAll it takes is a lot of time and sweat :-)

DeleteThe surface doesn't look very nice after sawing, but the boards are reasonably flat, so I can easily clean them up with a scrub plane.

At home I would never even consider doing it, but out here I haven't got any other options.

Brgds

Jonas

spanish cedar was the wood for cigar boxes....

ReplyDeleteThanks for the information, I am pretty sure that is the species.

DeleteIt seems pretty open grained and very easy to work with a sharp tool. It pares pretty easy cross grain.

Brgds

Jonas

I'm guessing, but I believe that cigar boxes were usually made of cedar. I'm not much of a re sawing type of a woodworker, but I like the idea, and you have to do what you have to do when your options are limited. And like you said, it's a good workout. As I said before, I go to the gym and lift weights for exercise, and let the table saw do the "heavy lifting" for me when I'm woodworking :). You will have to convince the ship owners that a bandsaw is a must for the carpenters mate.

ReplyDeleteI guess that I am a bit like the kids who would like to eat the ice cream, but not the oat meal porridge. I like to do the actual joinery like cutting dovetails and mortises etc. But I don't like to do the hard work that is necessary for me to get there.

DeleteI actually think that we have a hand held circular saw on board, but I am not too fond of those for re sawing small boards like this.

Actually I make the requisitions for tools on this ship, so theoretically I could order a band saw. But I kind of doubt that the company will be happy if I did it, so I'd better not.

I guess the wood could be a cedar, but I am not very good at identifying wood species that I don't normally work on.

Actually it doesn't matter what kind of wood it is, because I am pretty sure it will be great for my purpose, and it will probably end up being painted anyway.

Brgds

Jonas

Looks like it could be apitong.

DeleteThanks for the tip.

DeleteI'll try to google that species.

Brgds

Jonas

APITONG

ReplyDeleteDipterocarpus grandiflorus

Bagac, Philippine Mahogany (family)

Source: Philippine Islands

Color: Light to dark reddish-brown

Pattern: Grain slightly crossed; quartered "ribbon" often absent or wide apart.

Characteristics: Moderate to coarse texture; dull; hard and comparatively heavy; works and finishes will; good gluing and finishing qualities.

Uses: Heavy duty lumber; truck decking

Availability: Readily available mainly as lumber

Price Range: Average

Apitong is much more likely to stand the everyday shipboard abuse of a Jacobs Ladder much better than any cedar I know. Apitong makes a well wearing deck too. Looks like you'll be requisitioning a new Jacob's ladder soon, if you haven't already done so.

Thanks :-)

DeleteThe deck department have already requisitioned a new ladder, so this one was free for taking.

Actually the ladders is certified, so there is a company name that I could try to make a search for. Maybe they carry some information on their homepage as to what type of wood they are using.

Brgds

Jonas